Cutting Waste Through On-Demand Fabrication

One of the main impediments to success in any endeavor - be it industrial, creative or academic - is waste. It could take the form of wasted resources, wasted time or wasted opportunities to improve. In order to advance and see our full potential we must cut anything out of our process that doesn’t provide value. In other words, we’ve got to cut the waste.

This is one of the core concepts outlined in Jeffery K. Liker’s landmark book, “The Toyota Way” which explores the managerial programs that made Toyota one of the most efficient and successful manufacturers in the word. He’s quoted as saying, ““Most business processes are 90% waste and 10% value-added work.” As we’ve built up OSH Cut over the last three years, we’ve been determined to flip those percentages on their heads. .

There is a belief, maybe even a tradition at this point, in manufacturing that you divide every process up into separate departments. For example, all of your lasers are in one department, finishers in another, press brakes in another with all of the departments trying to push through as many parts as possible with minimal coordination. Each department runs under separate priority schedules with varying amounts of resources and manpower with no larger overall plan than “move everything you can onto the next department.” We saw this production philosophy to be rife waste.

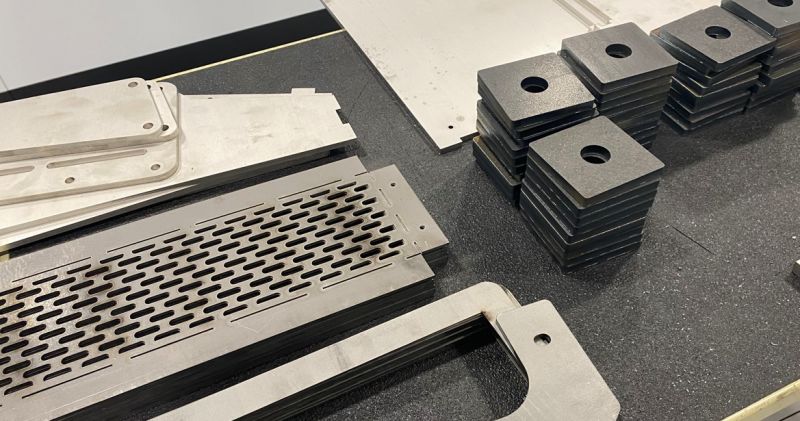

We instead decided to structure OSH Cut using a cell-based approach. In this approach, all of the manpower, machinery and infrastructure needed to produce the end product is consolidated into self-sustaining groups or cells staffed by fewer people who have a hand in production, from release to completion. All processes within the cell are connected and configured to make the most efficient use of time and resources, adding as much value as possible for the customer.

This approach is made possible by systems and controls that allow everyone assigned to the cell to see what is going on with each stage of production. This visibility allows everyone to be a part of the process and empowers them to speak up if they find an issue or a possible improvement. Our process has transformed from an assembly line orientation to a people-focused orientation. This allows us to get projects done much more quickly with less waste and more value to the customer.

We’ve further eliminated waste through our automated quoting and order system. We’ve gone to great lengths to create a quoting system worthy of the internet age where customers can immediately see their quote and have full transparency as to what’s included in it. They can change quantities and materials and get instant feedback on pricing and turnaround, not more waiting several days for each parameter change. There are no long-term contracts, not long negotiations or commitments. Just exactly what they need, exactly when they need it.

(shown above, our customer-facing quoting software provides instant prices and manufacturability feedback)

As we’ve grown and we’ve been able to serve so many customers, we often try to put ourselves in their place and imagine what it would take to create excitement. What do we offer that could take a manufacturer to the next level? We really think that one major value-add is reducing waste.

The traditional way for a manufacturer to work with a supplier might involve months going over contracts, and then contracting a monthly part volume regardless of manufacturing needs. After all of that, they’d get to start the whole process over again at the end of the contract period. That results in lots and lots of wasted time and inability to quickly adapt to changing market conditions. There had to be a better way.

Two of the big contributors to waste in an organization are Overproduction and Excess Inventory. Parts sitting on shelves waiting to be used or final products waiting to be sold constitute a huge cash investment and potential liability should market conditions or consumer trends change significantly. We firmly believe that on-demand fabrication is the solution to avoiding these huge sources of waste.

The concept of “Kanban” (the Japanese word for ‘card’) is a set of signs or signals that prompt specific actions within the process. This system is designed to avoid backups on the line and avoid overproduction or inventory issues. The system gets exactly the resources it needs, exactly when it needs them. Taking the time to visualize the entire process and set appropriate levels of material and labor creates significant efficiencies. For this to work, a company must ensure they have strong ties to their suppliers so that there is no interruption in work.

We truly believe that on-demand fabrication services, like what OSH Cut offers, could vastly improve a company’s ability to eliminate waste and create a Kanban system that works for them. Parts could be ordered to meet current demands without sinking a ton of money into unneeded inventory. They could better plan their processes to match their business cycle and create a more efficient manufacturing model. This significantly reduces waste due to overproduction or excess inventory and allows the company to be more nimble in it’s offerings. Keeping a few week’s inventory on hand with the knowledge that more could be ordered and delivered in 5 or fewer days would be a huge catalyst to growth.

Replacing the aging practice of long-term contracts and massive production runs with an on-demand model will have a transformative effect on the industry. Fabricated parts can be provided when they are needed quicker than ever before. Companies will be able to design efficient Just In Time production models that will give them peace of mind and additional capital to expand. It’s an exciting time, to be sure. We can’t wait to see what we’ll help them build!